Sustainability has been at the heart of everything we’ve done since we were a teeny tiny start up. We’re now moving towards completely plastic free packaging.

Sustainability has been at the heart of everything we’ve done since we were a teeny tiny start up. We’re now a B Corp, a member of The Microfibre Consortium and the Single Use Plastics Project.

80% of our products ships naked from our factory to us. We estimate this saves 300,000 plastic bags a year which reduces our consumption of plastic by over 30 tonnes a year.

Our Plastic Free Journey

- Our Process

- Plastic Free from Factory to Warehouse

- Plastic Free Packaging

- Our Work with the Single Use Plastics Project

Our Process

Our process is simple:

- Do we need an individual poly bag?

- If not, can we remove it and use a carton liner?

- If yes, we choose the smallest, recycled and most recyclable design. We then remove the poly bag at the warehouse for recycling via the EOG SUPP project.

Plastic Free from Factory to Warehouse

Our products come in two main categories: clothing and equipment. Factories use poly bags to protect products – from damage in transit, and from moisture damage. But all those plastic bags really do pile up.

If a product arrives in a poly bag from the factory, our warehouse heroes remove it to post it to you. This is so the bags can be collated and recycled in bulk. It means you won’t be awash with packaging and the responsibility is in our hands. (Oooft. Responsibility is heavy.)

Equipment

For equipment, it’s easy to remove the bag for product where it won’t affect function. Any product with a (highly unlikely!) minor aesthetic fault from damage in transit will hopefully soon be on a hill. Getting used. Abused. And covered in mud.

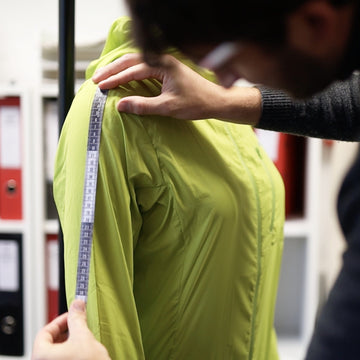

Clothing

For clothing, it’s a bit trickier. Especially for the supply chain. For insulated or waterproof clothing, their function can be reduced if they get wet or dirty. One solution we’re trialling is larger, recycled plastic bags to line the box. It reduces the number of poly bags. And they can be reused later down the line. Win win!

Our first plastic free packages were trialled with the Koulin base layers. We started planning in 2020. The first delivery arrived in 2021. We simply rolled up the base layers and wrapped them with a bit of card. There was no increase in return rate!

We’re slowly working on removing poly bags from all orders that we can. By winter 2022, we will have removed poly bags from all products except high-value, more fragile products like down jackets and waterproofs.

Plastic Free Packaging

Part of being an online retailer is that we need packaging to get your goodies from the warehouse to your hands. That packaging is functional. It keeps your new kit safe and sound! It also needs a couple of extra bits and bobs like an address label and branding. And preferably it needs to be easy to handle in the warehouse. But how do you reduce the environmental impact of mailing bags?

Before 2019, we used 100% recyclable polyethylene mailing bags.

Pros:They were durable, waterproof and protective. We could reuse them for returns and – better yet – they were cheap.

Cons:They used natural resources. And they had low recycling rates because you couldn’t recycle them at home.

In February 2019, we started using sugarcane ethanol mailing bags.

Pros:They were 100% recyclable! These mailers were also durable, waterproof and protective. They were manufactured from a renewable source. And sugarcane captures CO2.

Cons:They had low recycling rates due to unclear messaging. They also led to deforestation and reduced biodiversity in growing areas in Brazil.

In April 2021, we started using FSC certified paper mailing bags.

Pros:Paper mailing bags are biodegradable, FSC approved and recyclable at the kerbside. They’re manufactured locally in the UK. Paper is more circular than plastic and paper mailers can be used for returns. Our mailers have a high recycled content. The virgin content is certified from managed and renewable sources with full chain of custody.

Cons:Paper mailers aren’t perfect either. Because they’re heavier and bulkier than plastic, transportation costs and energy are higher. They have a higher carbon footprint than poly bags, they’re less weatherproof, less durable and less affordable. Unfortunately, they also have a higher concentration of toxic chemicals compared to single-use plastic bags.

"Over our history we have moved from polyethylene to bio-based polyethylene to paper. While the pros and cons are still very lively debated, the thing that has swung our decision to paper is the ease and simplicity of the recycling process. And planting more trees can only be good right?” – Kenny Stocker, Alpkit Co-Founder

Our Work with the Single Use Plastics Project

Who are they?

The Single Use Plastics Project (SUPP) is run by the European Outdoor Group (EOG). They bring together outdoor brands across Europe to work on the problem of single use plastic packaging. Collaboration is always better.

What do they do?

SUPP do lots and lots of academic research. They work with brands. Collecting data, studying and feeding back. They teach us what we can do to make poly bags more reusable and more recyclable.

How does this impact us?

Every time you recycle something, you downgrade the quality. We do everything we can to keep the recycled product just as good as the original. This is about reducing impact where we can’t eliminate it.

That’s why all our poly bags are 100% recycled. We’re also changing them to a pillow closure design, meaning they can be recycled into a purer product. And we can reduce the amount of print on the poly bag.

The Single Use Plastics Project sum up our ethos wonderfully:

“.the best possible poly bag is no poly bag, and we encourage and support aggressively prioritising elimination strategies. Where poly bags are still necessary, however, we have developed a set of standards to minimise contaminants and ensure the maximum value of the material is retained. This is not the solution to all single use plastics, but a collective step in the right direction.”

![Kraft [Mens]](http://us.alpkit.com/cdn/shop/files/KRAFT_MENS_1.jpg?v=1762542951&width=768)

![Werk [Mens]](http://us.alpkit.com/cdn/shop/files/WERK_MENS_OUTER-SPACE_TENERIFE_005982__4000px.jpg?v=1717552503&width=768)

![Kepler Short Sleeve [Mens]](http://us.alpkit.com/cdn/shop/files/mens-kepler-short-sleeve-2026-stirling-temp.jpg?v=1768762939&width=768)

![Kepler Short Sleeve [Mens]](http://us.alpkit.com/cdn/shop/files/mens-kepler-short-sleeve-navy.jpg?v=1768762939&width=768)

![Kepler Short Sleeve [Womens]](http://us.alpkit.com/cdn/shop/files/womens-kepler-short-sleeve-2026-cosmos-temp.jpg?v=1768417177&width=768)

![Kepler Short Sleeve [Womens]](http://us.alpkit.com/cdn/shop/files/womens-kepler-short-sleeve-cosmos.jpg?v=1768417177&width=768)